Process initialization & optimization from single part to automated series production

- Process development, optimization and process qualification

- Development, manufacturing and delivery of FSW tools

- Process acceptance, audits & standardization issues

- Design & implementation of QA measures (online and offline)

- Support with prototyping, pre-series and production ramp-up

Component design, process introduction, knowledge building & implementation.

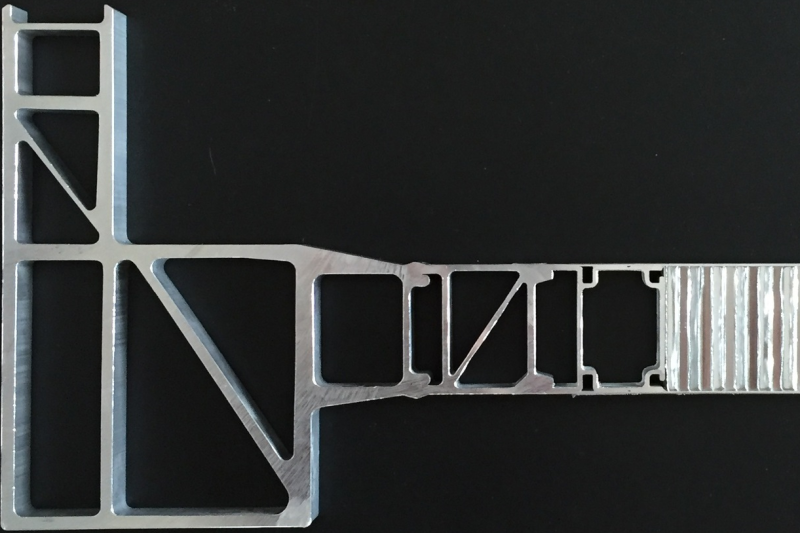

- Friction stir welding-compatible product design, adaptation and optimization

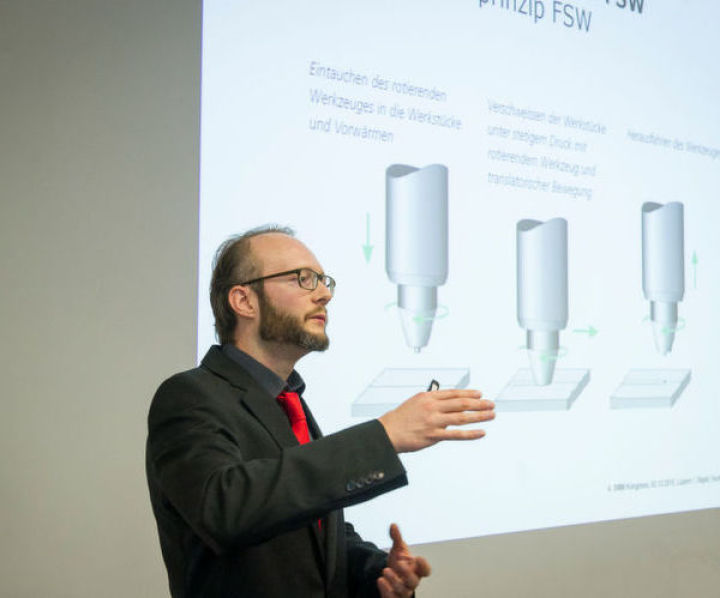

- Coaching and support of project teams, also with your end customers

- Service life evaluations & optimization of FSW welded products.

- Training and qualification of your personnel according to ISO 25239:2020

Feasibility studies, prototyping and initial sample production

- Functional and process-oriented component design

- Process optimization and component validation with documentation according to ISO 25239:2020

- Manufacturing of samples and monitoring of the qualification process

- Early implementation on series systems according to customer requirements

Highly specialized project support

- Troubleshooting on site, worldwide

- Support from project planning to commissioning of friction stir welding systems

- Contract development and research